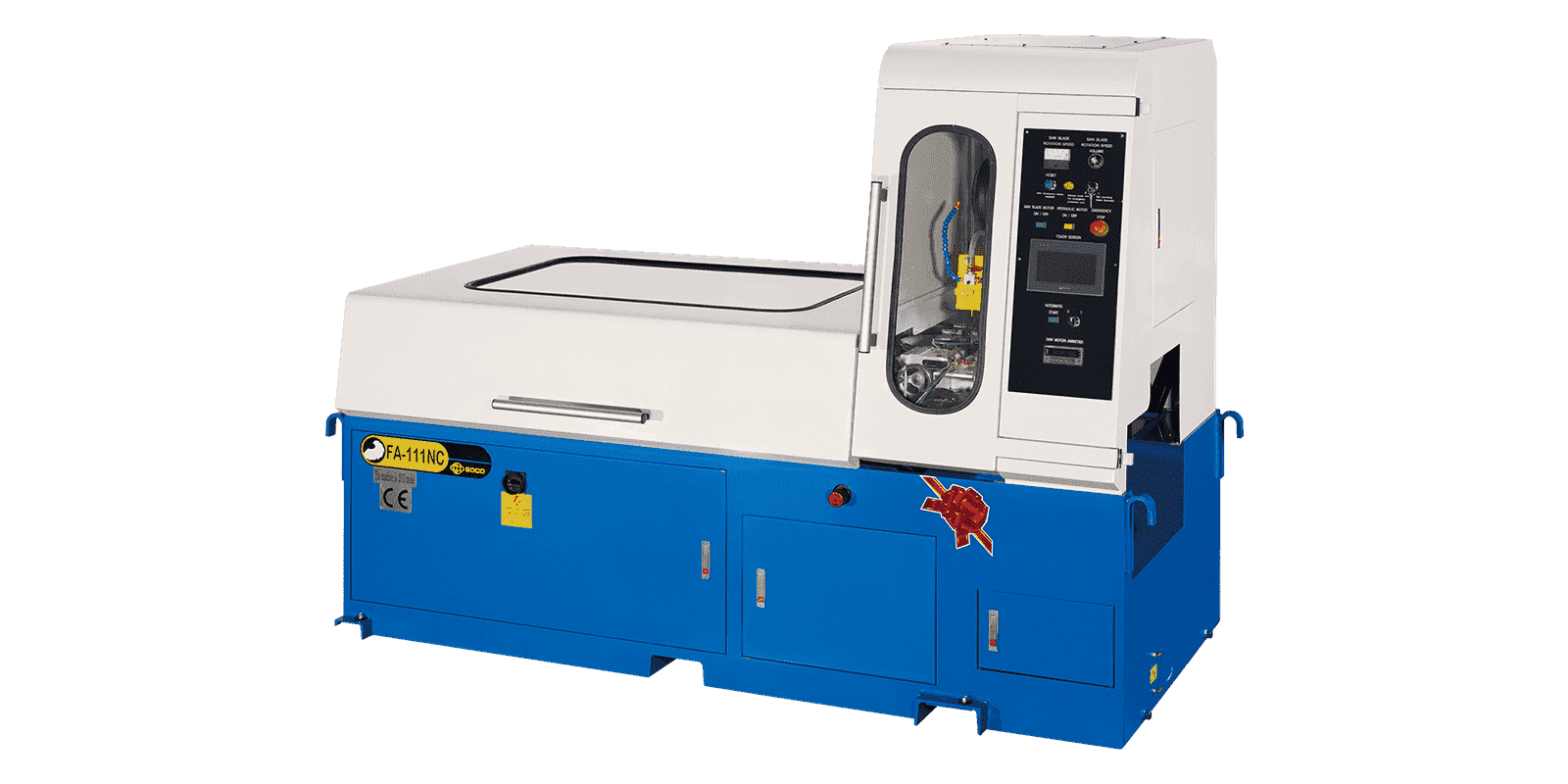

Excellent results in cutting a wide variety of materials, from mild steels to high-strength steels, stainless steel and copper materials

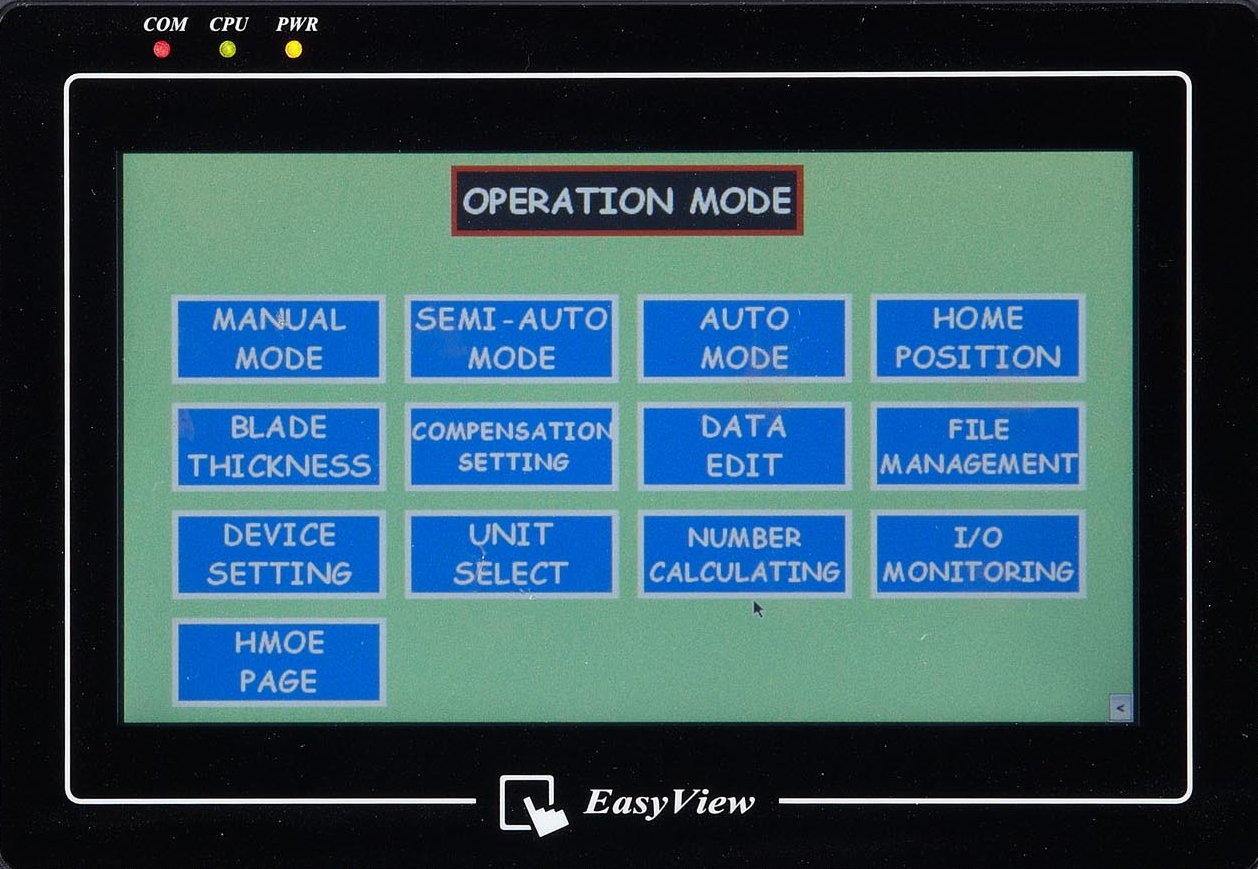

Easy to create and save files with PLC control circuit, user-friendly interface with touch screen

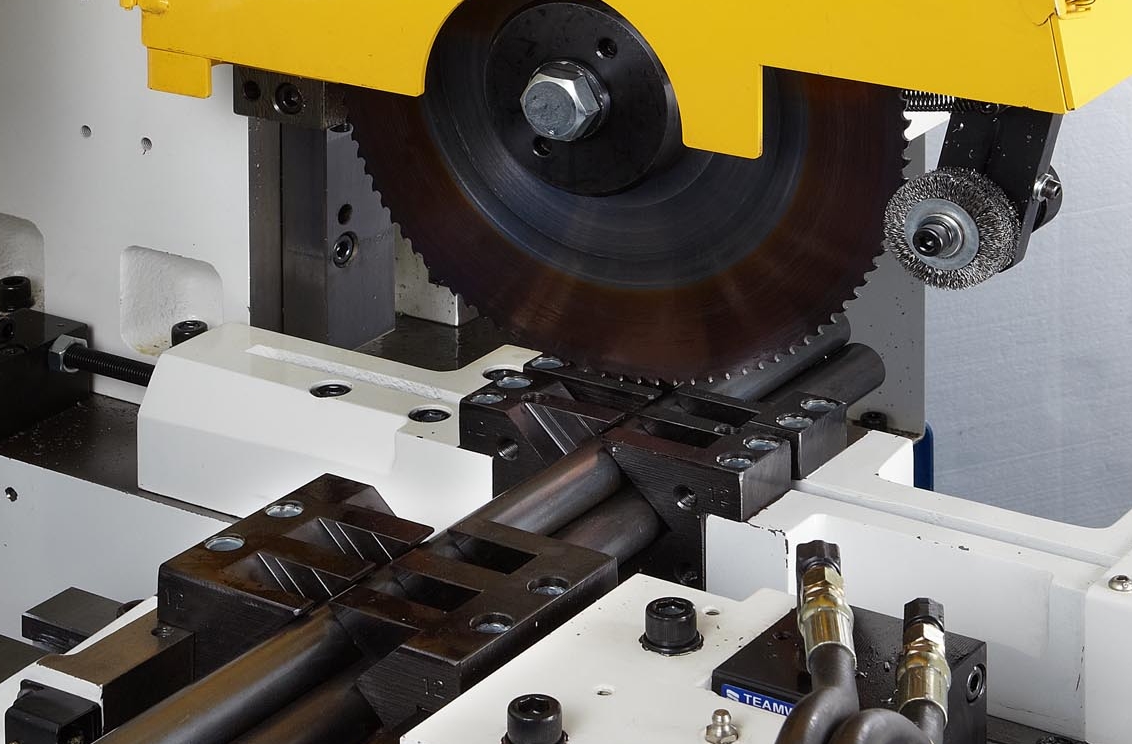

90 Degree vertical moving cutting head provides strong and high precision cuts

Achieving precision up to +/- 0.05-0.1mm in cutting lengths by the electric servo feeding system (head of stroke)

SOCO patented gearbox eliminates the backlash and provides longer tool life.

SOCO patented feeding system provides more sensitive material feeding, rigid main clamp provides much safer material clamping.

Automatic lubrication system provides more ideal working conditions, circulating cooling system provides better surface quality

Saw protection electronic device and protection cover provides safer working

Piece setting, counting and automatic stop can be adjusted digitally

Easy cleaning and maintenance with built-in chip box

Easier tube feeding length adjustment by digital unit

Maximum 1000mm feeding stroke and unlimited number of feeding.

STANDARD ACCESSORIES

1) 1 Set of Standard V type jaws

2) 1 set of Digital Readout Unit

3) 1 Set Inverter

4) 1 Set Tool Box

5) 1 User Manual