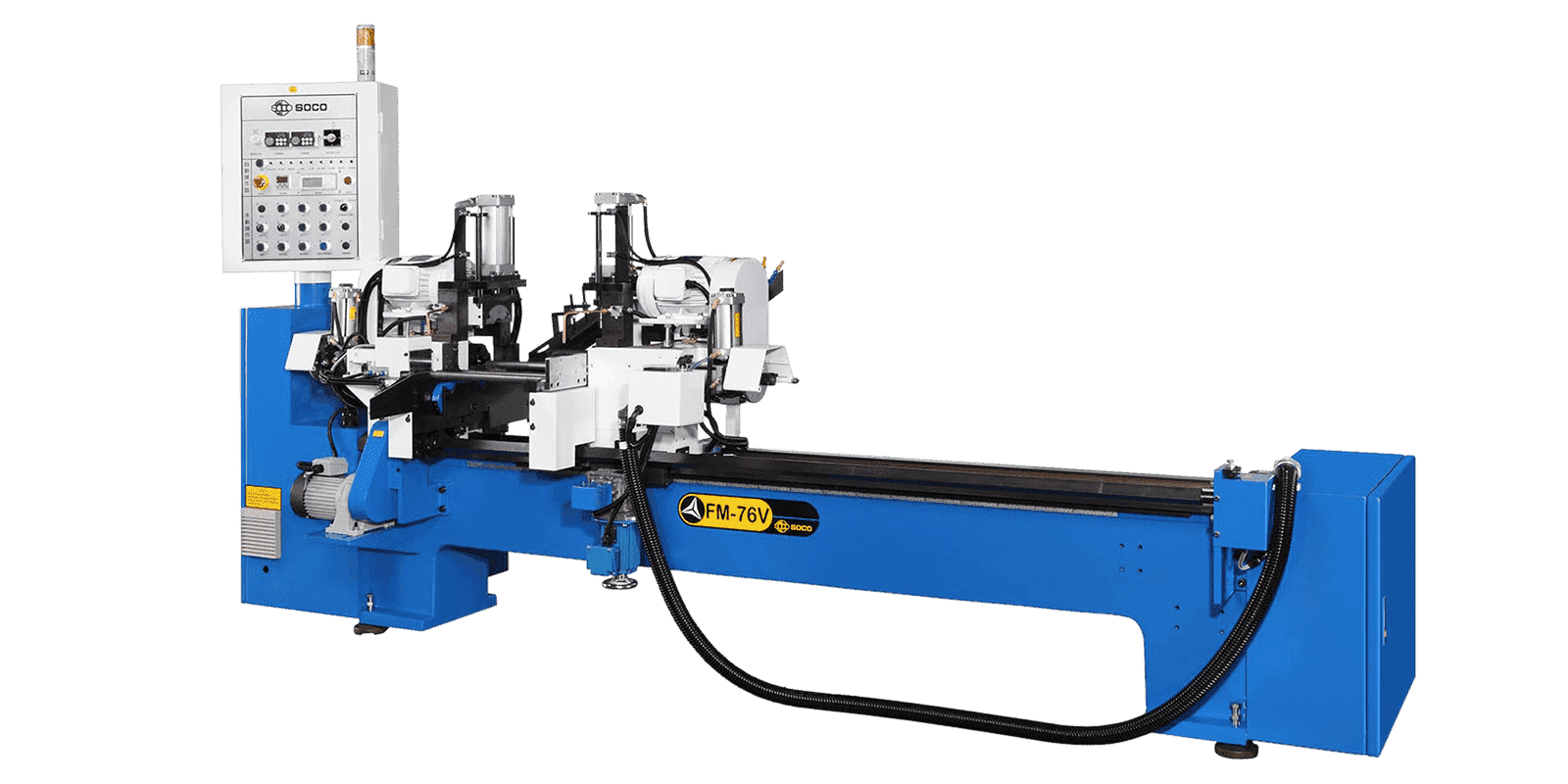

With its Fully Automatic loading magazine, uninterrupted loading and chamfering prevents loss of labor and cost. (Optionally, BTM Bundle Loading Magazine can be added)

Ability to inner and outer chamfering, length measuring on both sides of the tube in a single process

Precise material feeding with NC Control

Desired length can be adjusted quickly with easy adjustment of the movable right head,.

When the desired quantity is reached and products are out of the specified tolerances, the machine's automatic stop feature prevents over or wrong product production.

It is designed for tube and solid material and suitable for steel, stainless steel, copper and aluminum materials. (Optional speed inverter can be added.)

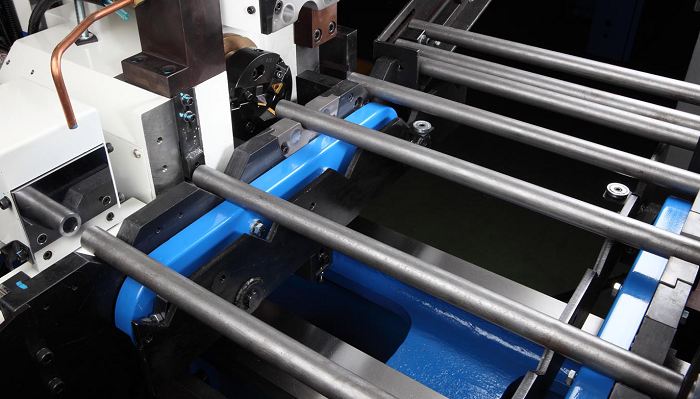

Chamfering depth up to 15mm and chamfering up to 15 degrees in inner and outer chamfering

Simultaneous external surface cleaning, inner and outer chamfering of the tube

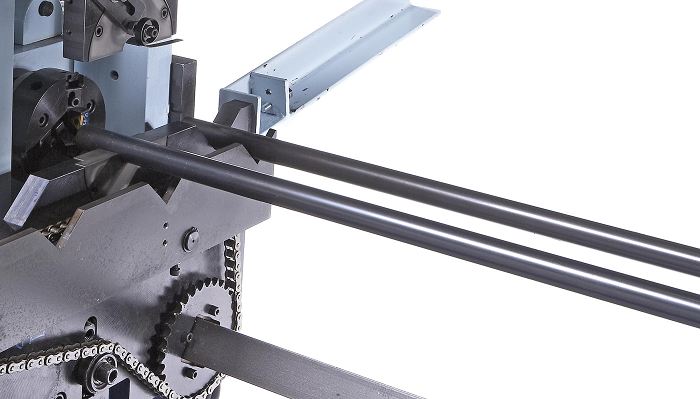

Perfect surface quality by the patented material feeding system

Time losses are prevented by the easily replaceable tool holder system,.

Long-life carbide tips are designed for heavy use

It offers less maintenance costs by its perfect electrical infrastructure and PLC control

While the two tool holder heads on the machine approach the material quickly in the first step, preventing time loss, in the second step, tool breakages are prevented with its slow movement and perfect surface quality is achieved.

Possibility of +/- 0.05 mm length tolerance in length completion by the easily adjustable depth device

Ability to measure height with +/- 0.02 mm precision

Specially designed strong machine bed, absorbs vibration and sound, providing smooth, stable and silent operation.

STANDARD ACCESSORIES

1) 1 Set of Clamping Jaws

2) 1 Set of Tool Head and Tool Holder Set

3) 1 Set of Length Measurement System

4) 1 Set Tool Box

5) 1 User Manual (English)

OPTIONAL ACCESSORIES

1) Inverter

2) Transition to Full Hydraulic System

3) 2 or 3 Meter Length processing

4) Special tools for smaller diameters

5) BTM Loading Magazine