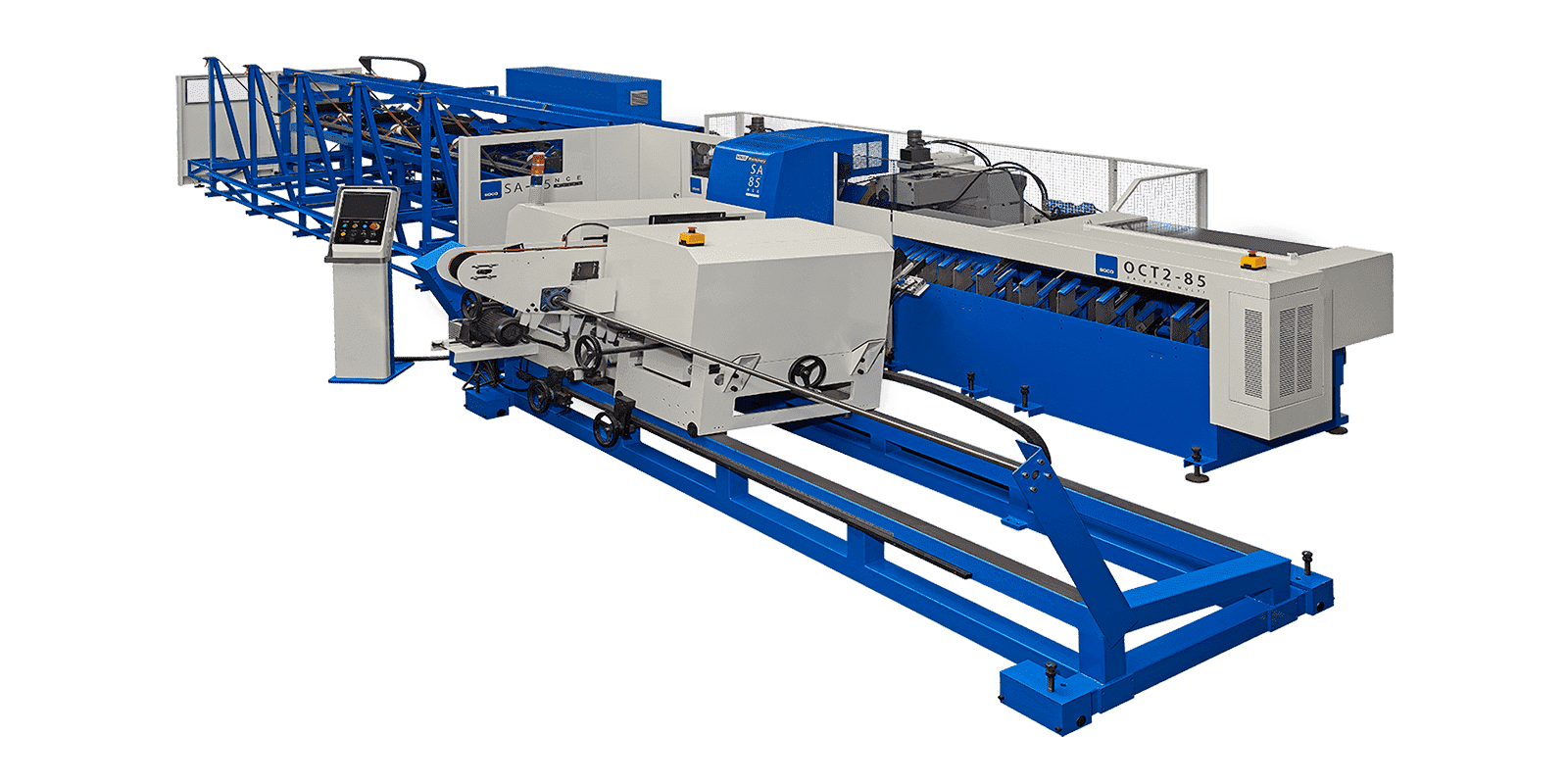

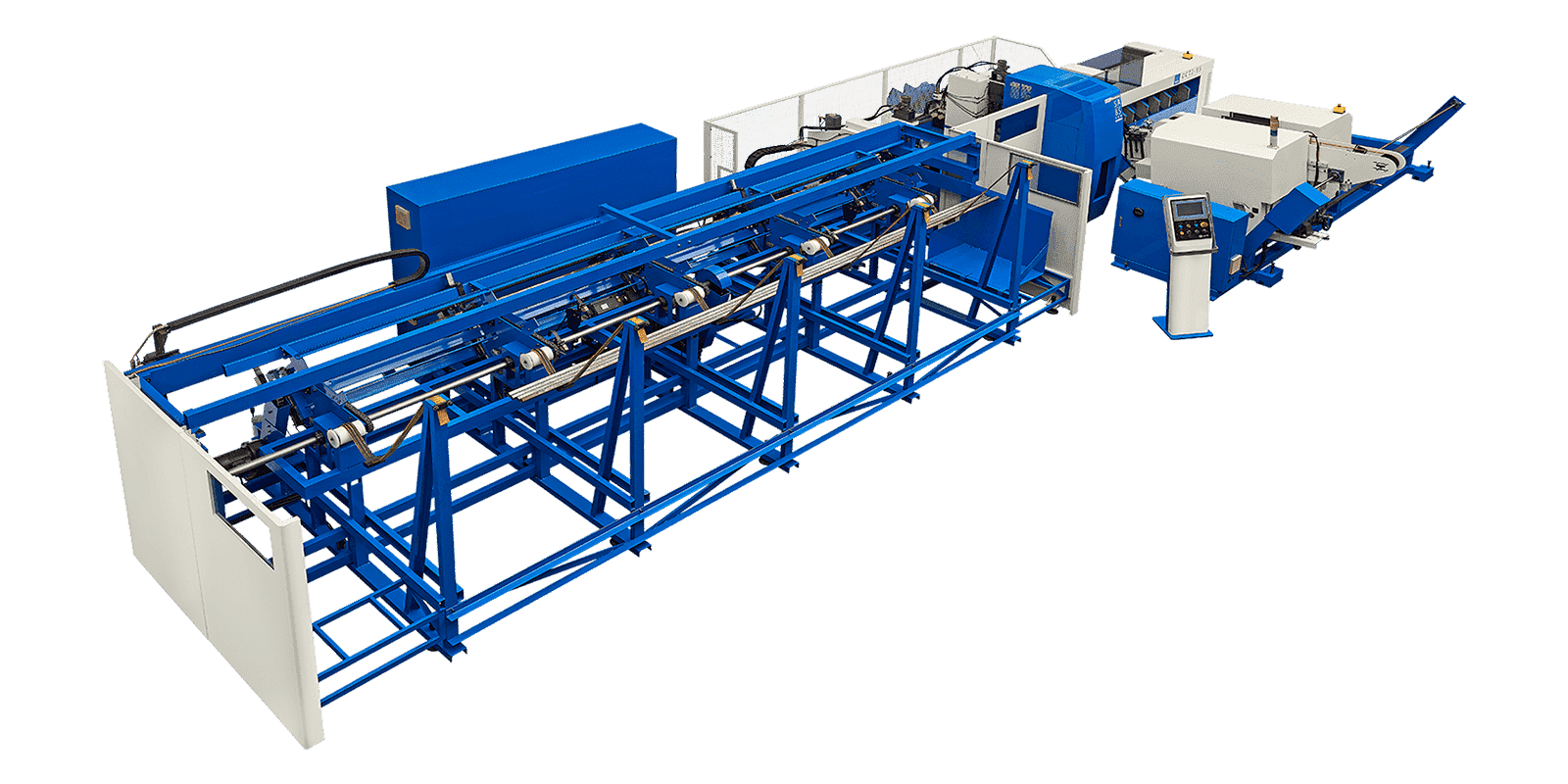

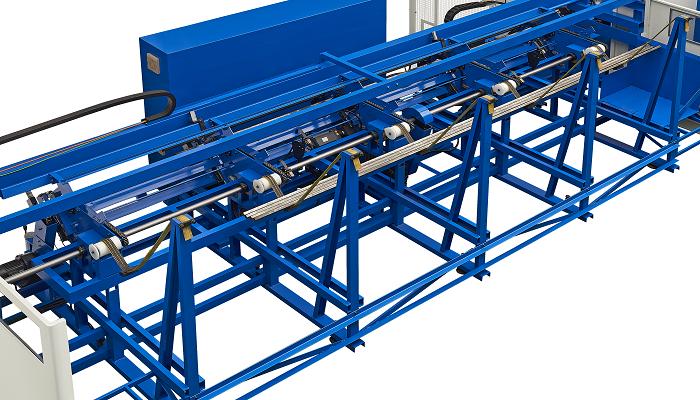

Fully automatic tube cutting system with 1.2 second cycle time or over 3000 products per hour by its high-speed cutting feature.

It can cut multiple materials simultaneously, automatically align and pack the cut materials.

Excellent cutting performance by the automation system equipped with 7 electric servos

I. Material alignment (3 Axis)

ii. Cutting

iii. Feeding

iv. Unloading

v. Refeeding

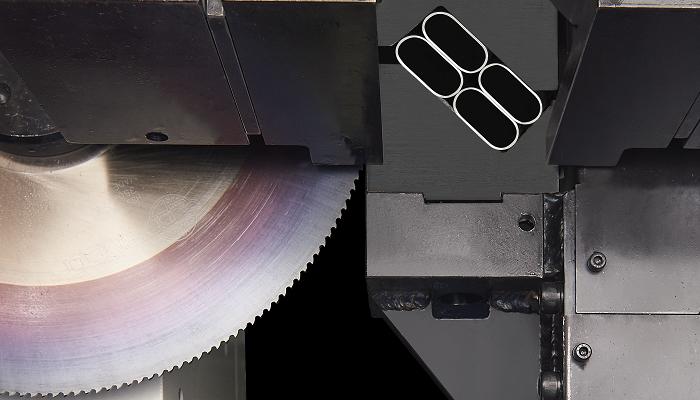

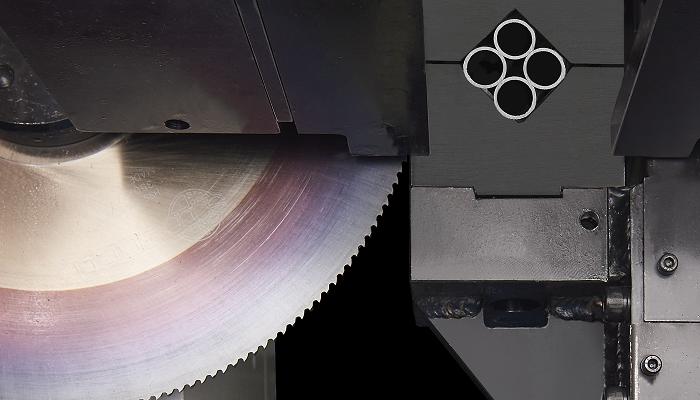

It allows cutting mild and stainless tubes at high performance with HSS circular saw.

It has a 6 meter bundle type automatic loading magazine.

Even if there is material in the vise area, it ensures that the amount of new material is minimized by applying new material.

Allows material discharge to be programmed in different positions when connected with SOCO's end finishing machines

It ensures that the first and last waste can be automatically separated from the cut materials.

By the speed (RPM) inverter, it allows to make appropriate speed adjustment for cutting different types and sizes of materials.

Much faster setting time for cutting size changes.

Improved saw changing system allows to change the saw faster and minimize downtime.

its special structure can be easily coupled to SOCO's automation system devices.

Washing Unit (TWD-90)

Deburring Unit (BDB-70)

Length Measurement Unit (LM)

Chamfering Unit (FM-76V)

Packaging Unit (NGO)

STANDARD ACCESSORIES

1) 1 Set of 6 Meter Bundle Type Loading Magazine

2) 1 Set Inverter

3) 1 Set Automatic Chip Conveyor

4) SOCO i2 Patented Control System and Graphical Touch Screen Interface

5) 1 Set Tool Box

6) 1 User Manual