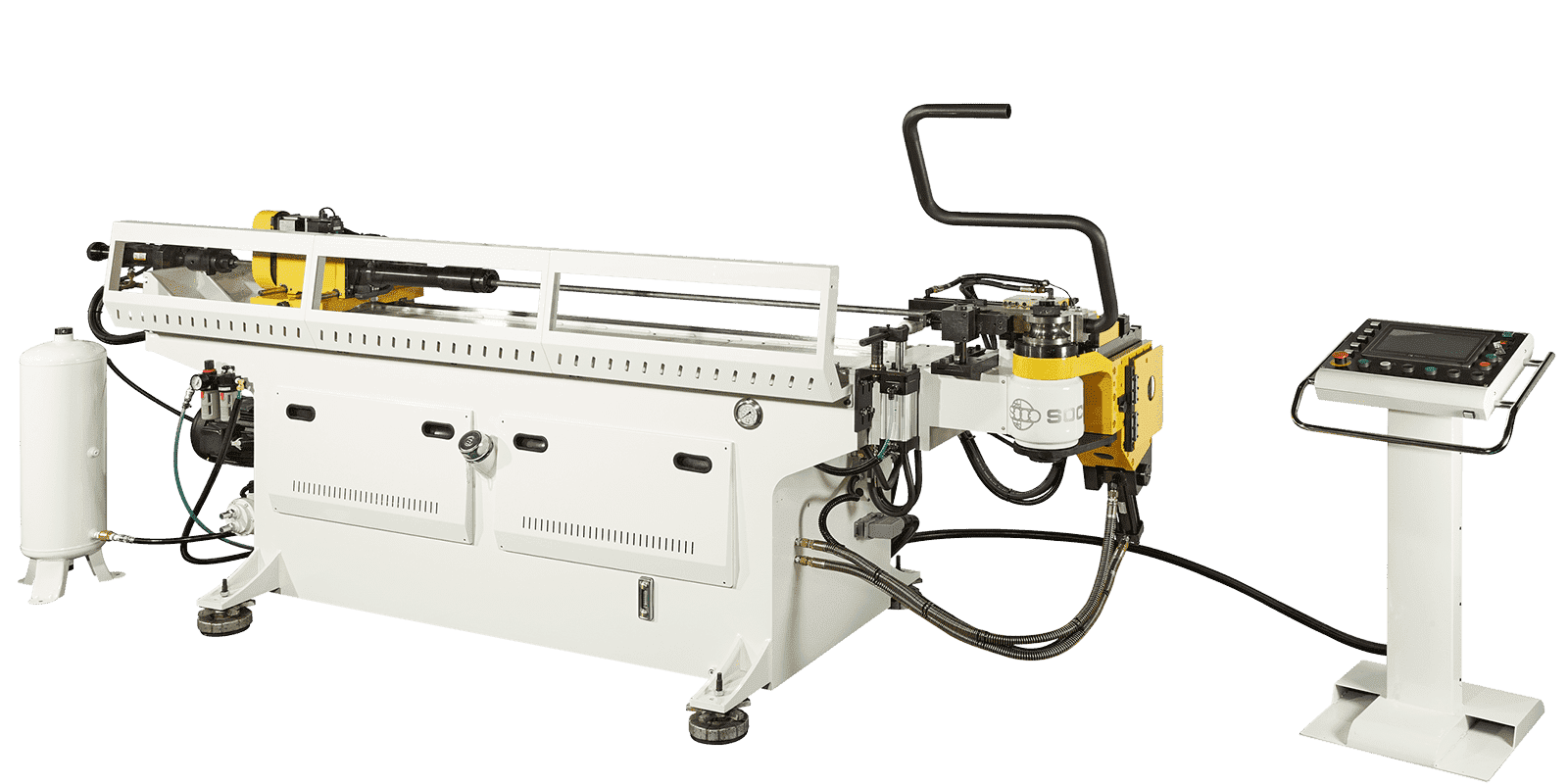

Programmable 3-Axis CNC pipe bending machine

SOCO Patented DGT gear system provides strong, fast and highly precise repeatable bends.

Six (3) Axis Electric Servo or Hydraulic Control

- Feeding (Servo)

- Rotation (Servo)

- Bending (NC - Hydraulic)

Perfect success in bending difficult tubes with its powerful hydraulic system

Ability to bend up to six different radii in one tube with mounted up to six stacks.

Electric Servo controlled axes have separate speed control for each and perfect synchronization of simultaneous movements are provided.

Able to bend either chuck open or clamped for every bend.

The Movable Machine Control unit provides great ease of use to the operator.

All electrical circuits and components are mounted into specially designed protective cabinets with safety in mind, and the connection for the safety mat has been prepared.

STANDARD ACCESSORIES

1. 1 Piece Mandrel Rod

2. 1 Set Automatic Slide Lubrication System

3. 1 Set of Pressure Die Seat

4. 1 Piece SOCO Tube Bending Software

5. 1 Set Movable Operator Control Stand

6. 1 User Manual (English)

OPTIONAL ACCESSORIES

- Automatic Mandrel Lubrication System

- Double Stack System

- Stack Support Rod

- Radiator Type Hydraulic Cooler System

- Security Fence System

- Laser Light Barrier