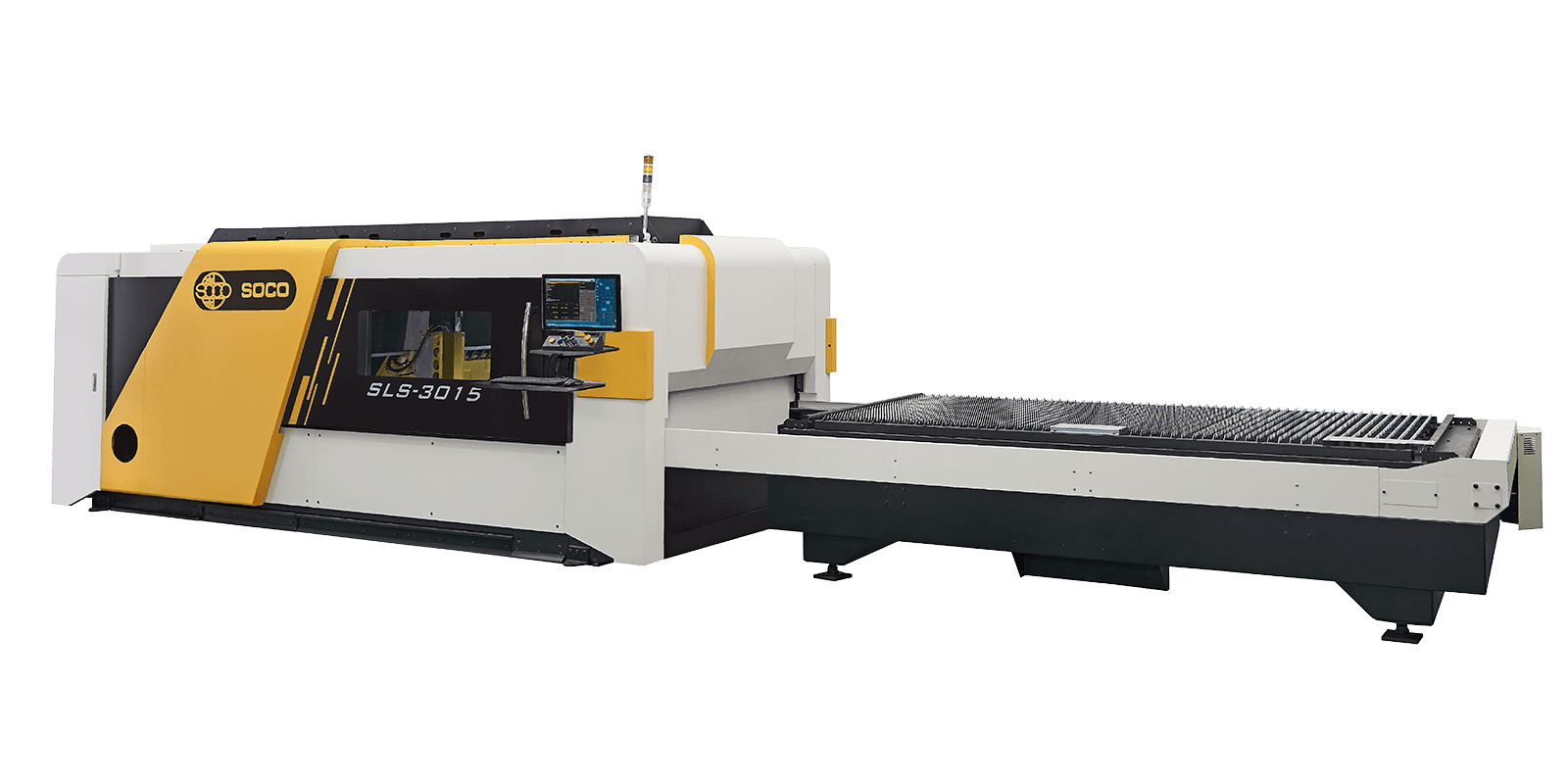

Achieve outstanding cutting results with SLS-3015, the SOCO All-Linear Fiber Laser Cutting Machine for sheet metal.

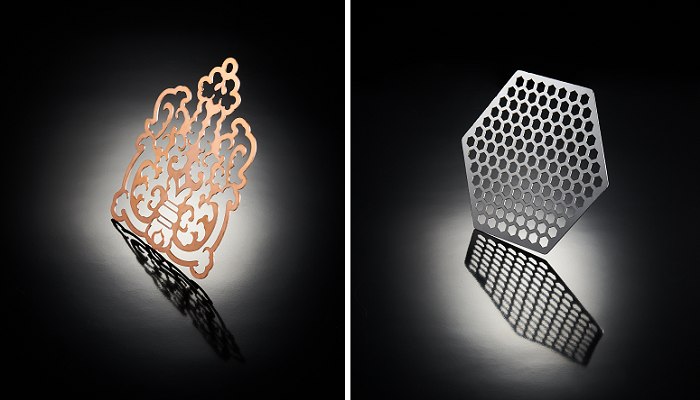

Precise, compact, easy to use, and quick to install, SLS-3015 has low maintenance costs, zero backlashes, and without the need for periodical calibration. This unique machine can process a wide range of materials and thicknesses with high performance and extremely high accuracy cutting.

All-Linear = Superior Design

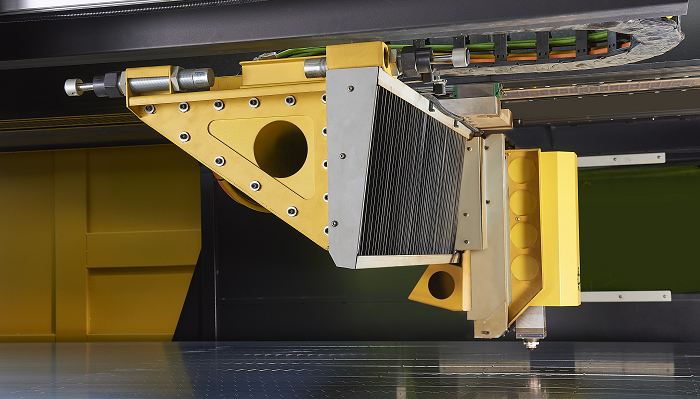

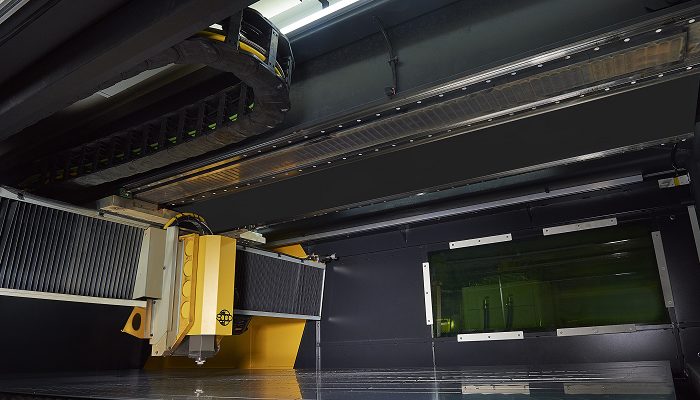

This patented design and technology ensure the highest acceleration, cutting speed, and accuracy in laser cutting. The contactless cutting process brings continuous accuracy over time, no wear-out, and low maintenance costs.

Direct Drive Linear Motors XYZ + Close Looped Controls

With all 3 axes driven by linear motors, there are no axis synchronization issues typically associated with gantry-style machines or with hybrid types (servo + linear motors).

Speeds may reach up to 250 m/min and acceleration 2.5G. Each axis is equipped with optical scales, with a resolution of 0.5 µm, resulting in precise positioning of the cutting head and high accuracy cutting.

Max Utilization of Fiber Laser Technology

The combination of Linear Drives design and Fiber Laser technologies is ideal in achieving maximum cutting efficiency and the lowest cost per part.

PROCESSING CAPABILITY

- Cutting

- Bevel cutting

- Threading/notching/grooving

- Drilling holes

- Planer/slot opening

- For cutting complex size materials.

- Easily converts 2D/3D CAD files to compatible SOCO-CAD software.

- It replaces traditional workbenches and minimizes labor and material waste costs by providing ease of use.

PRECISION

Positioning ± 100 micron/m

Repeatability ± 50 microns

Measuring Clarity/Resolution ± 0.5 micron

STANDARD ACCESSORIES

One 3 Axis Linear Type Electric Servo SOCO SLS-3015-Fiber Main Machine

One 3050mm x 1550mm Material Table

One High Power Laser Rezenator (4kW)

One Laser Cutting Head; With automatic rangefinder sensor and quick lens changer system

One High Pressure Proportional Valve; For Auxiliary Gas

One Laser Resonator Cooling Unit

One Cutting Head Cooling Unit

One Cooling Unit for Linear Motors

One Smoke Extraction System

One Set of Auxiliary Cut-off Gas Connector

One Set Connector for Cooling System Gas

One Set Touch Screen CNC Control System

One SOCO-CAD Licensed

One IRMS system utility kit

One Set of Lens

One Set Nozzle (Ø1.2-1.5-2.0) and 1 Protection Glass