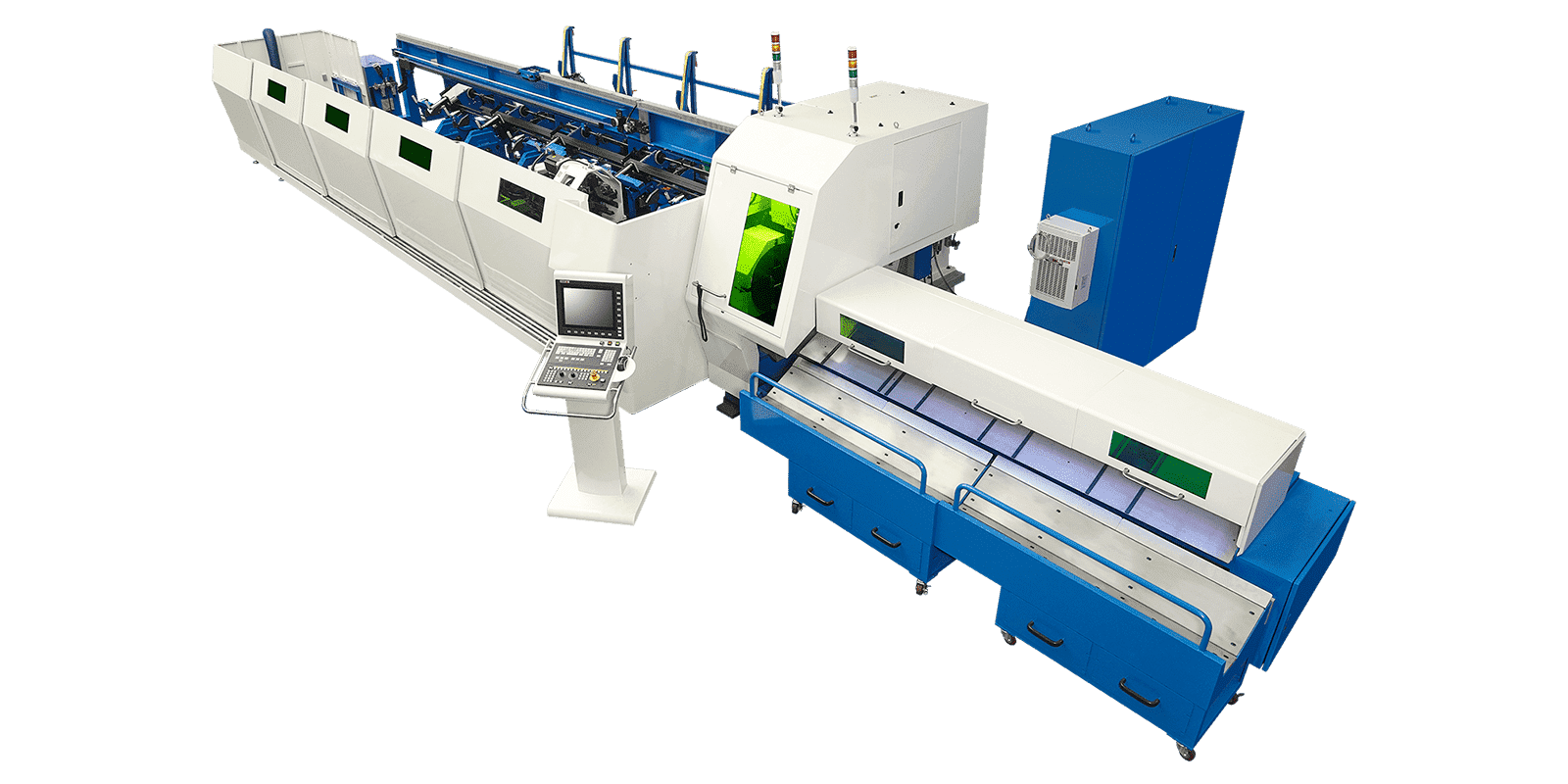

SOCO SLT-102-FIBER is a Tube Laser Cutting System that can easily cut metal tubular components of different shapes. Perfect for higher tensile strength materials, SLT-102-FIBER ensures no deformation or damage on the parts processed. The machine can join multiple processes in one system, saving production time and reducing labor costs.

Manufacturers and fabricators can create automated production lines integrating SLT-102-FIBER with other SOCO solutions such as chamfering, deburring, length measuring, stacking, and washing.

SLT-102-FIBER Tube Laser Standard Features :

- Laser tube cutting capacity up to O.D. 102 mm

- 1kW Laser Source (Standard), 700W and 2kW Laser Source (optional)

- Max. Lengths of working piece 3M (Standard) / 4.5 M / 6M

- Max. Wall thickness up to 6 mm (1 kW) / 9 mm (2kW)

- Automatic Bundle Loading System with Material Alignment

- SOCO CAD-CAM system for Tubes and Profiles with Built-in Nesting

- SOCO i2 (Intelligent Interface) 3D CNC Software Controls

- Cutting round, square, rectangle, and various profile shapes

- Laser Resonator + Cutting Head Cooling

- Vacuum Chip Extraction systems

- Scanning and Measuring Material before Cutting

- Compensation after Material Measuring

Laser Tube Cutting for Various Shapes

- Round Tube

- Square Tube

- Rectangular Tube

- Oval Tubes

- L-shaped profiles

- C-shaped profiles

- Mild Steel, Stainless Steel, and Aluminum

Automation Working Processes:

- Automatic Tube Bundle Loading

- Automatic Material Alignment

- Automatic Feeding and Rotation

- Fiber Laser Tube Cutting

- Unloading

STANDARD ACCESSORIES

One SOCO SLT-102-Fiber Main Machine with 7 or 11 Electric Servos

One Feeding Unit with Rotating Unit (6500 mm )

One High Power Laser Rezenator (700W – 1kW – 2kW)

One Laser Cutting Head; With automatic rangefinder sensor and quick lens changer system

One High Pressure Proportional Valve; For Auxiliary Gas

One 6500mm Loading Magazine (Bundle)

One Unloading Magazine with Two Outputs (3000 mm)

One Laser Resonator Cooling Unit

One Cutting Head Cooling Unit

One Smoke Extraction System

One Set of Auxiliary Cut-off Gas Connector

One Set Connector for Cooling System Gas

One Set Touch Screen CNC Control System

One SOCO-CAD Licensed (To be installed on another computer)

One Industrial Computer with High Capacity CF Card/ USB Connection/ Ethernet Interface

One IRMS system utility kit

One Set of Lens

One Set of Feed Axis Clamping Jaws(1x12-55mm; 1x15-65mm; 1x65-102mm)

One Set of Tube Rotating Rollers (1x12-90mm; 1x15-102mm)

One Set Nozzle (Ø1.2-1.5-2.0) and 1 Protection Glass